Shredders help humans manage waste for recycling and other purposes. There are many types of shredders, from simple paper shredders to bigger, high-tech hammermills and disintegrators. Small businesses and homes usually use the simpler, smaller types of shredders, while larger corporations, industries, and government entities may invest in more sophisticated shredders. One reason why such industrial-grade shredders are used by these entities is to protect confidential information and make sure that no one can piece it together later on. For this purpose alone, shredders are a vital part of our society.

Shredders help humans manage waste for recycling and other purposes. There are many types of shredders, from simple paper shredders to bigger, high-tech hammermills and disintegrators. Small businesses and homes usually use the simpler, smaller types of shredders, while larger corporations, industries, and government entities may invest in more sophisticated shredders. One reason why such industrial-grade shredders are used by these entities is to protect confidential information and make sure that no one can piece it together later on. For this purpose alone, shredders are a vital part of our society.

Industrial shredders are designed to efficiently shred every material from thin plastics and tissues to beverage containers and corrugated boxes in an efficient manner. These state-of-the-art devices take up a lot of space and even have special voltage lines. They are usually assigned their own designated area for shredding operations to make sure that safety can be maintained.

They are built to destroy large volumes of material in a quick and efficient way. They are also responsible for ensuring that the waste is compact and can be disposed of easily. They are designed with cutting edge technology to ensure that operations can be managed with negligible to no human intervention. This is to ensure that no accidents occur around the machine which can result in injuries or even death.

The most common benefit of industrial shredders is that they result in the eco-friendly disposal of waste and can dispose of sensitive business information safely. There are many different types of industrial shredders all the way from tire recycling shredders to paper shredders.

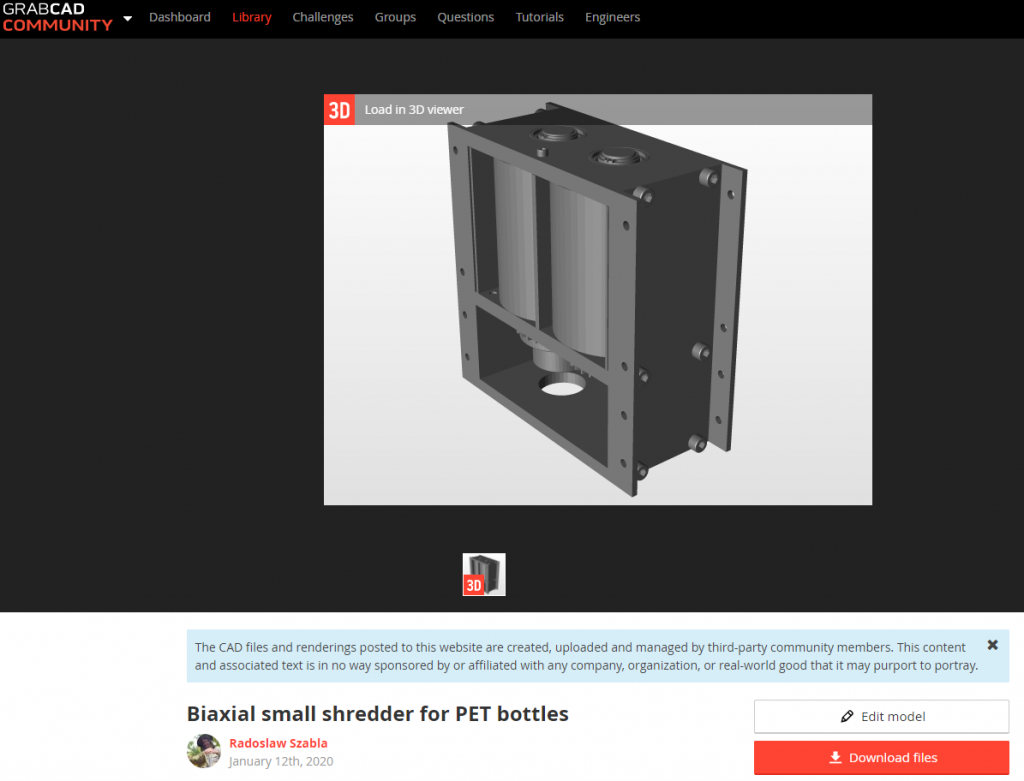

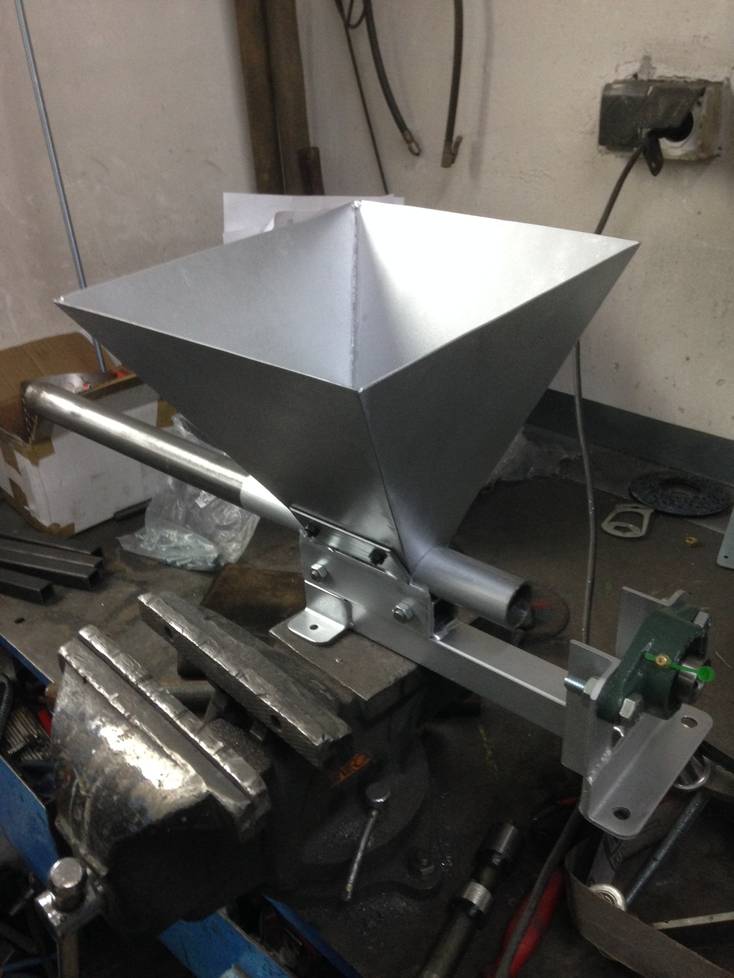

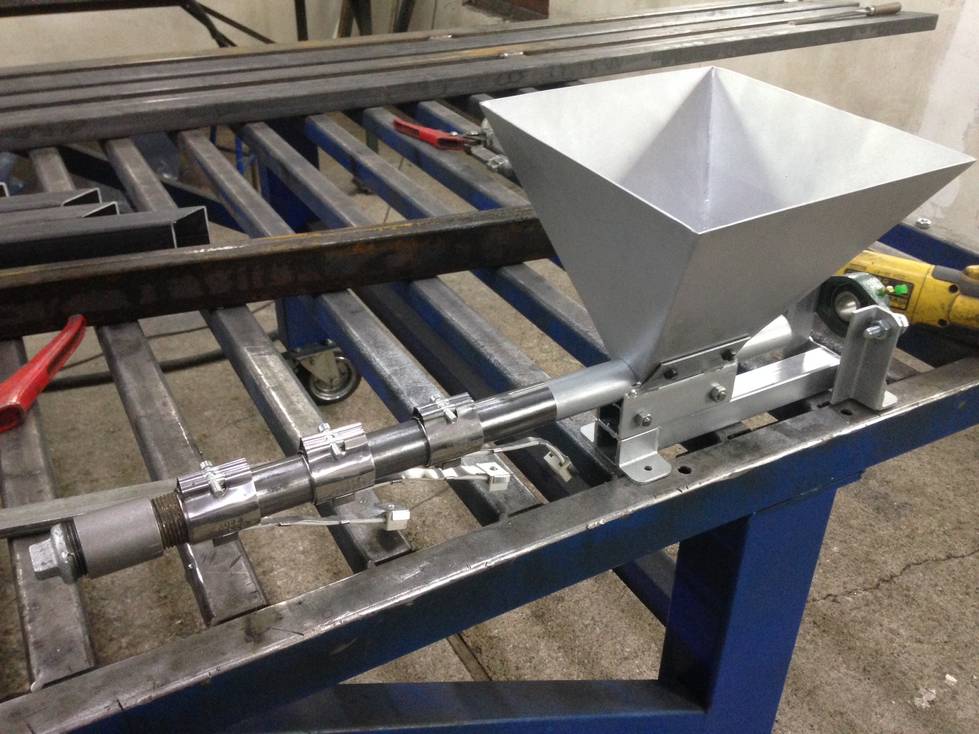

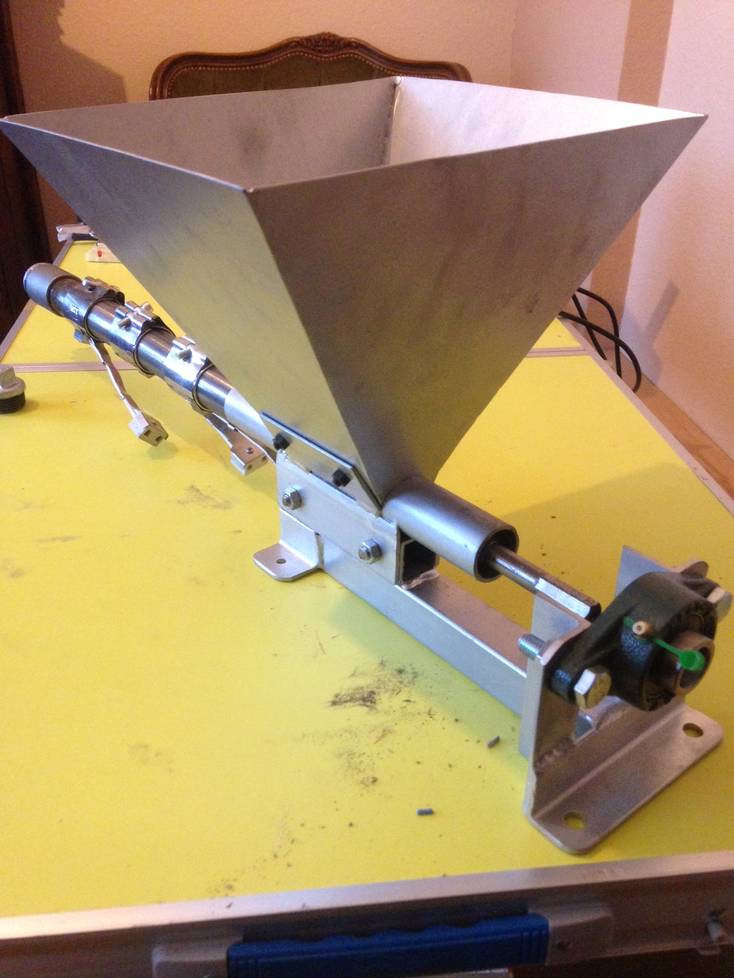

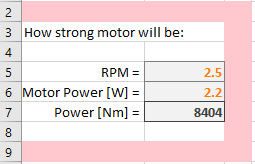

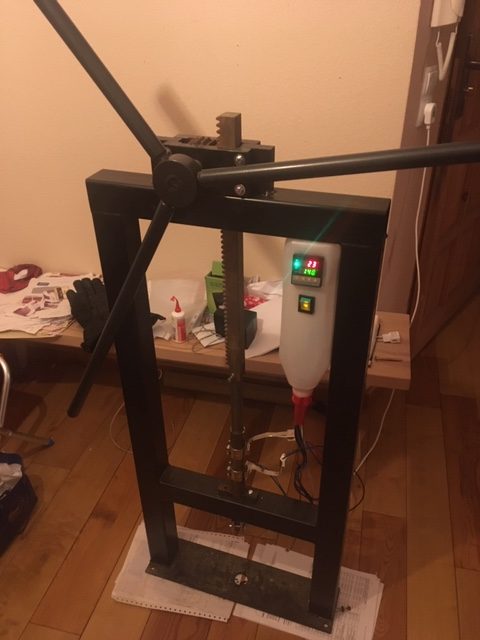

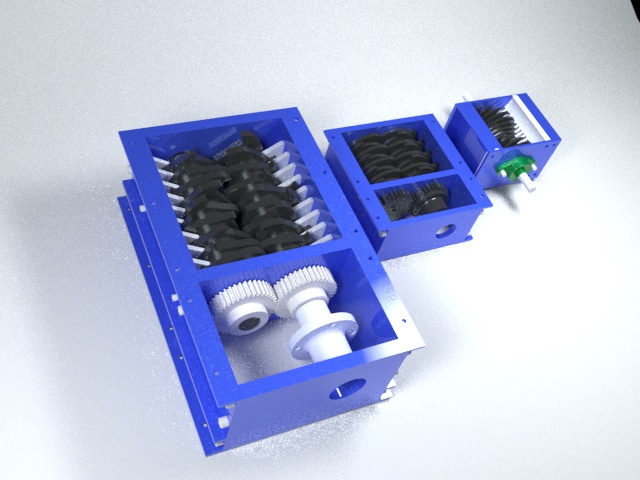

Different Types of shredder designs , which can be made. and soon I will be adding new one HDD Shredder.

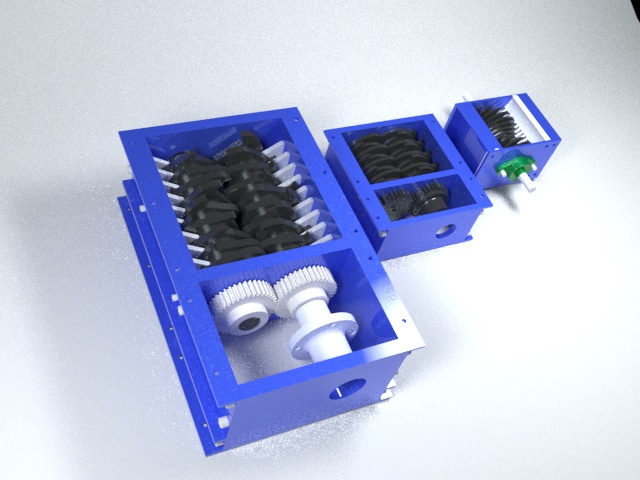

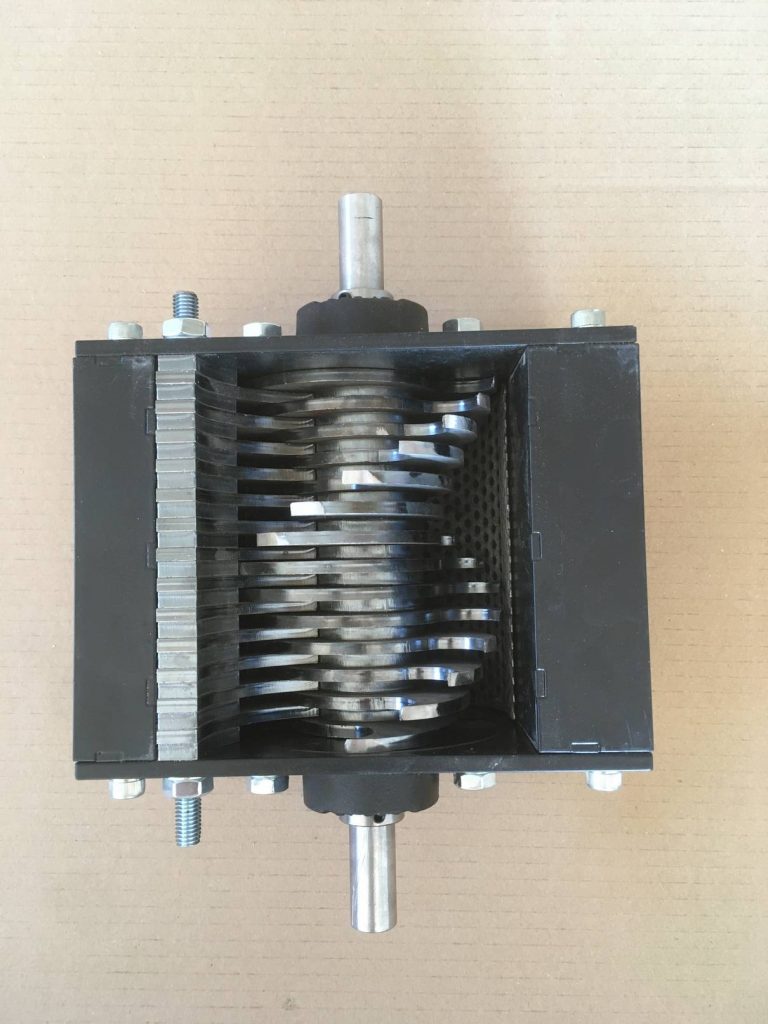

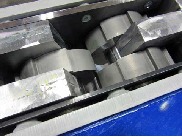

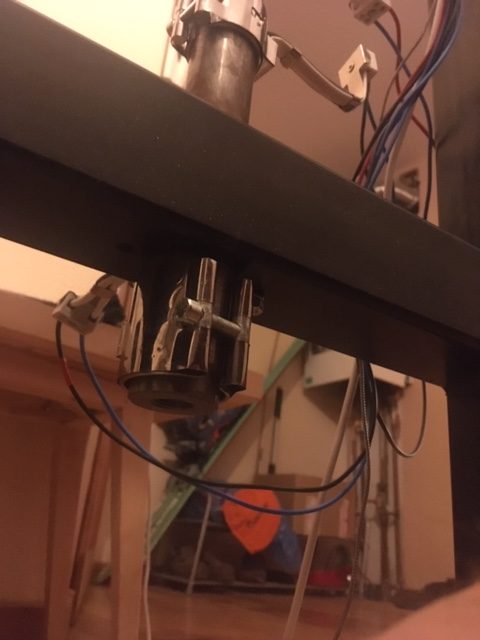

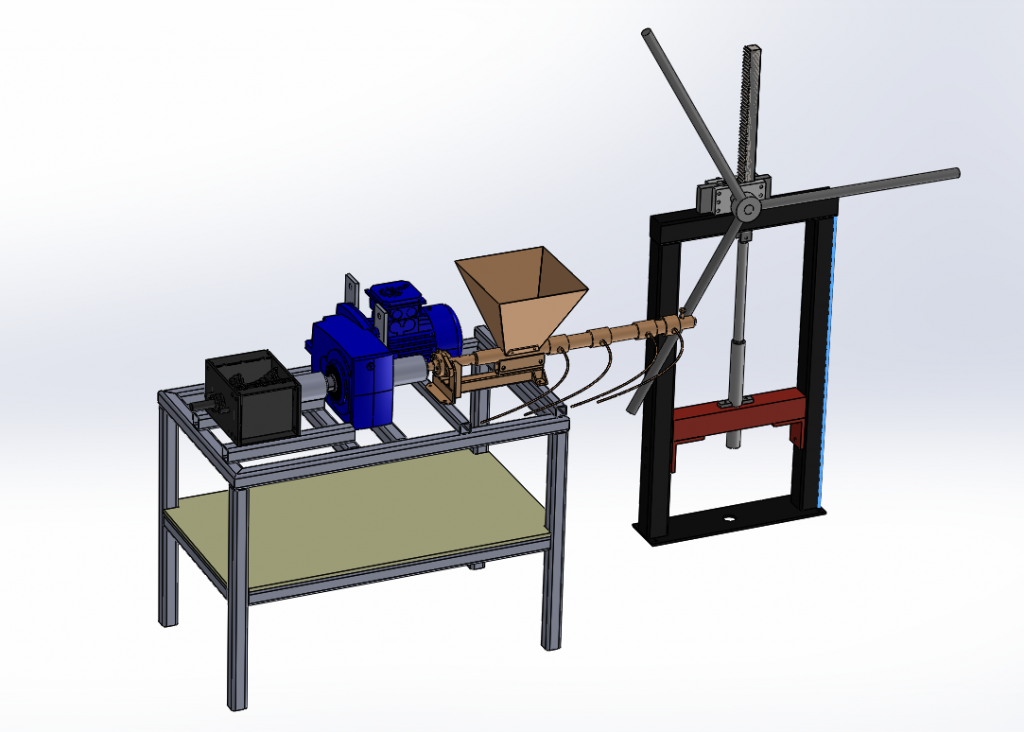

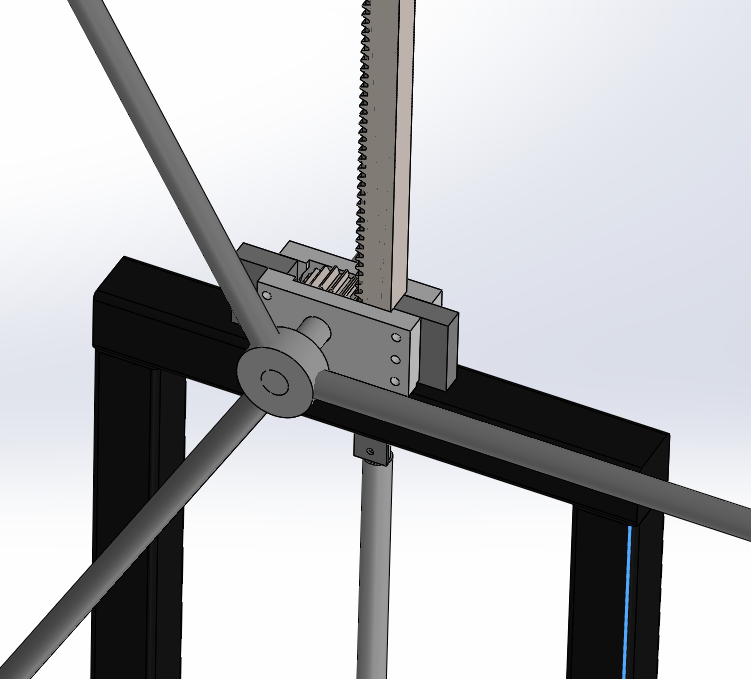

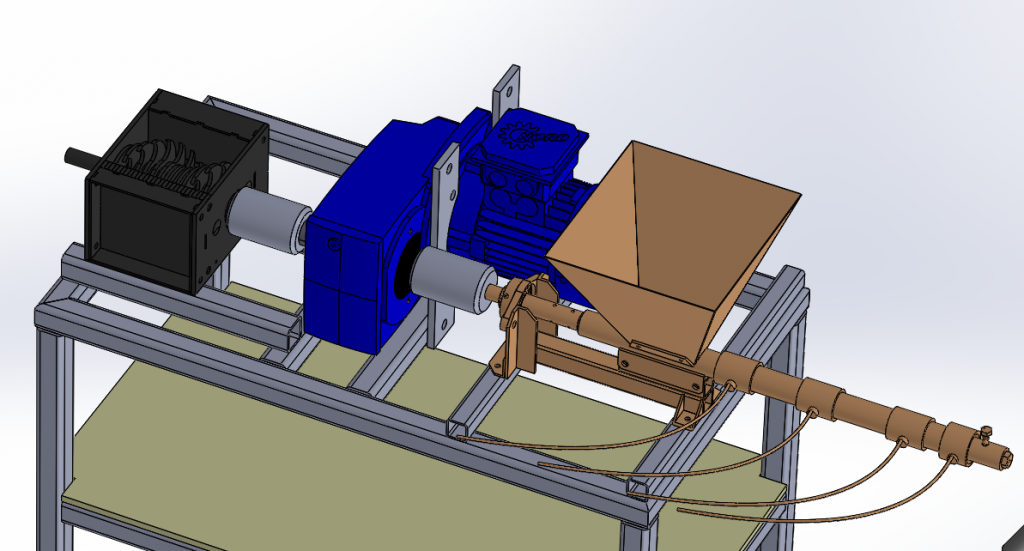

Rigth now the machines are looking like this :

-

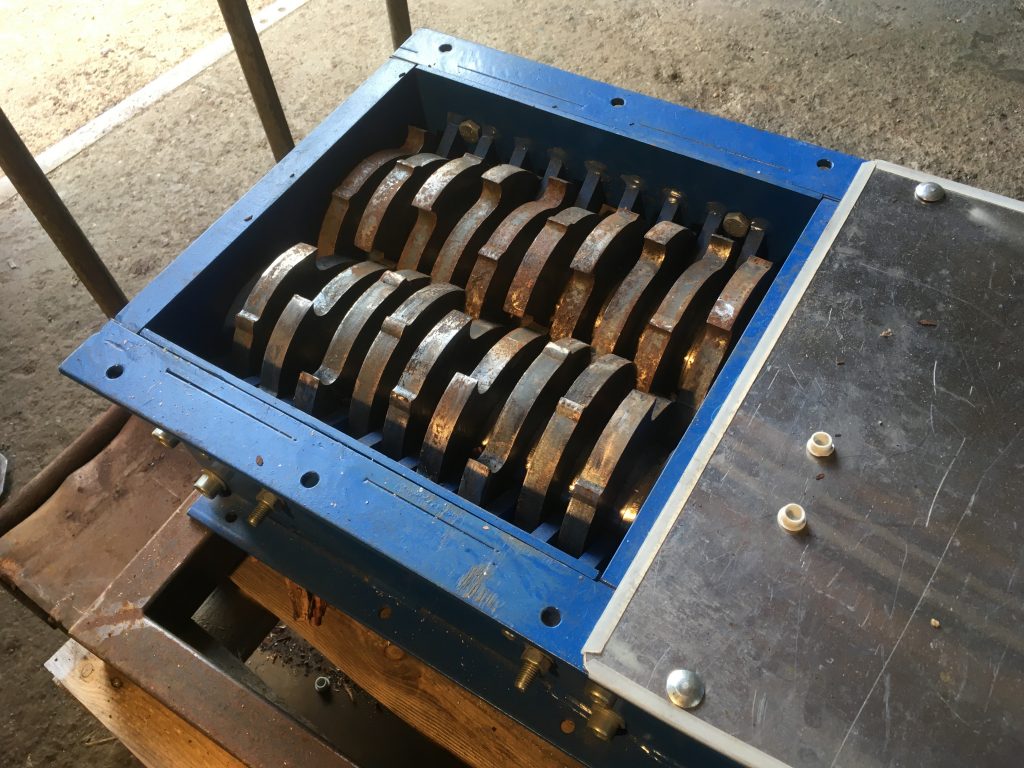

Big shredder 280mm x 220mm working area.

-

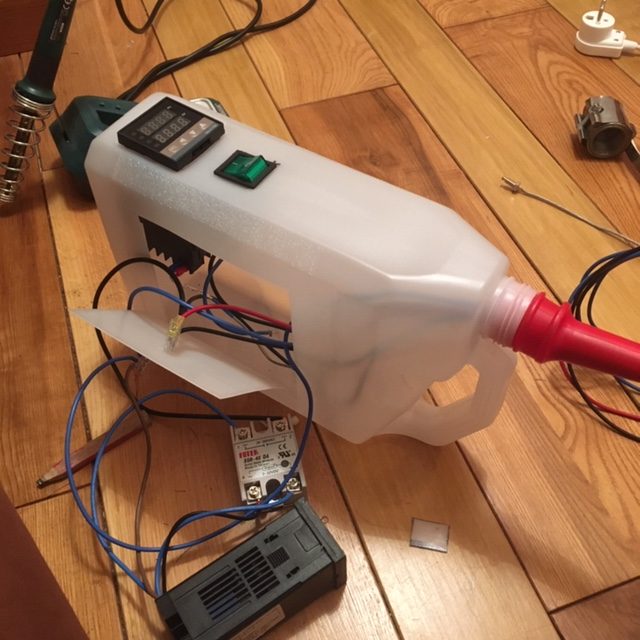

Medium shredder 150mm x 180mm working area

-

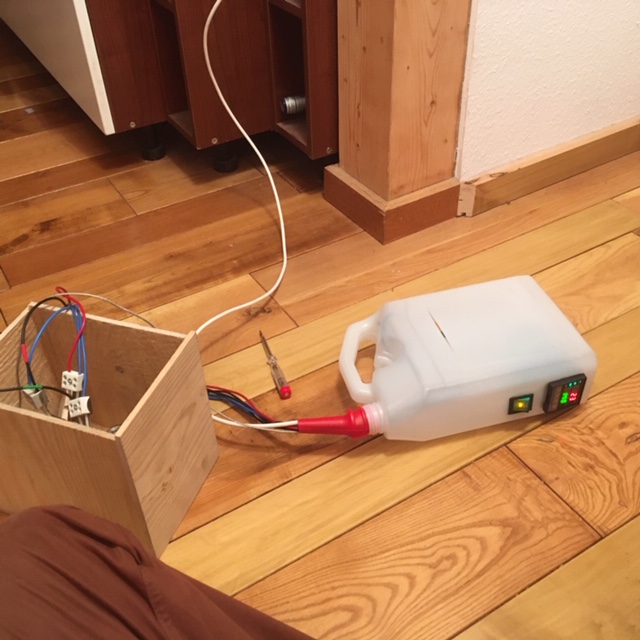

precious plastics shredder 125mm x150mm working area

Shredders help humans manage waste for recycling and other purposes. There are many types of shredders, from simple paper shredders to bigger, high-tech hammermills and disintegrators. Small businesses and homes usually use the simpler, smaller types of shredders, while larger corporations, industries, and government entities may invest in more sophisticated shredders. One reason why such industrial-grade shredders are used by these entities is to protect confidential information and make sure that no one can piece it together later on. For this purpose alone, shredders are a vital part of our society.

Shredders help humans manage waste for recycling and other purposes. There are many types of shredders, from simple paper shredders to bigger, high-tech hammermills and disintegrators. Small businesses and homes usually use the simpler, smaller types of shredders, while larger corporations, industries, and government entities may invest in more sophisticated shredders. One reason why such industrial-grade shredders are used by these entities is to protect confidential information and make sure that no one can piece it together later on. For this purpose alone, shredders are a vital part of our society.