Plastic pollution has become an ever-growing concern, permeating nearly every aspect of our environment. To truly understand its impact and the potential for change, let’s delve into the history of plastic, its adverse effects on the environment, and the innovative ways we can transform this pollution into opportunities for a better future.

**The Genesis of Plastic:**

The inception of plastic dates back to the 19th century, offering humanity a versatile and durable material. Initially celebrated for its convenience and adaptability, plastic production soared over the decades. However, the widespread use of single-use plastics and the lack of efficient waste management systems led to its pervasive presence in our ecosystems.

**Unveiling Environmental Consequences:**

The repercussions of plastic pollution are distressingly evident. Our oceans, once teeming with life, now harbor immense patches of floating plastic debris. Landfills overflow with discarded plastic items, while wildlife suffers from ingestion and entanglement. Microplastics infiltrate soil and water sources, posing a threat to ecosystems and human health alike.

**Redefining Waste:**

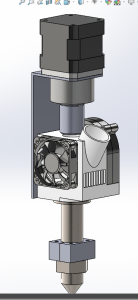

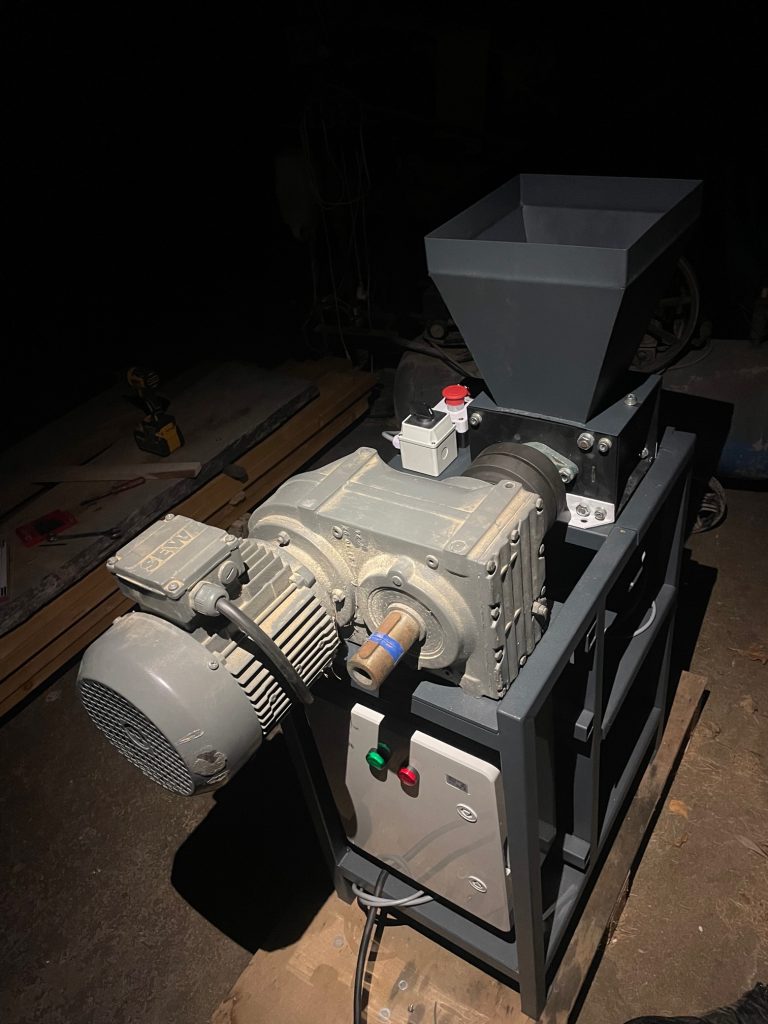

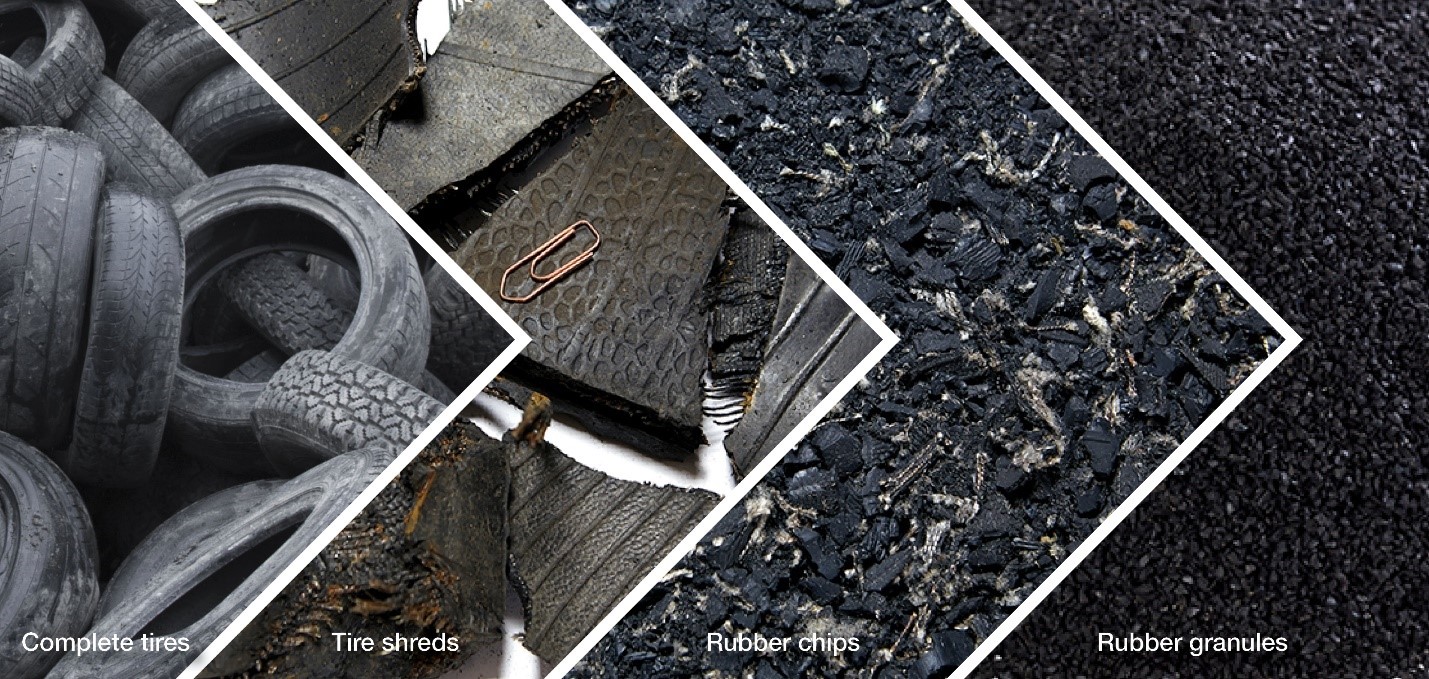

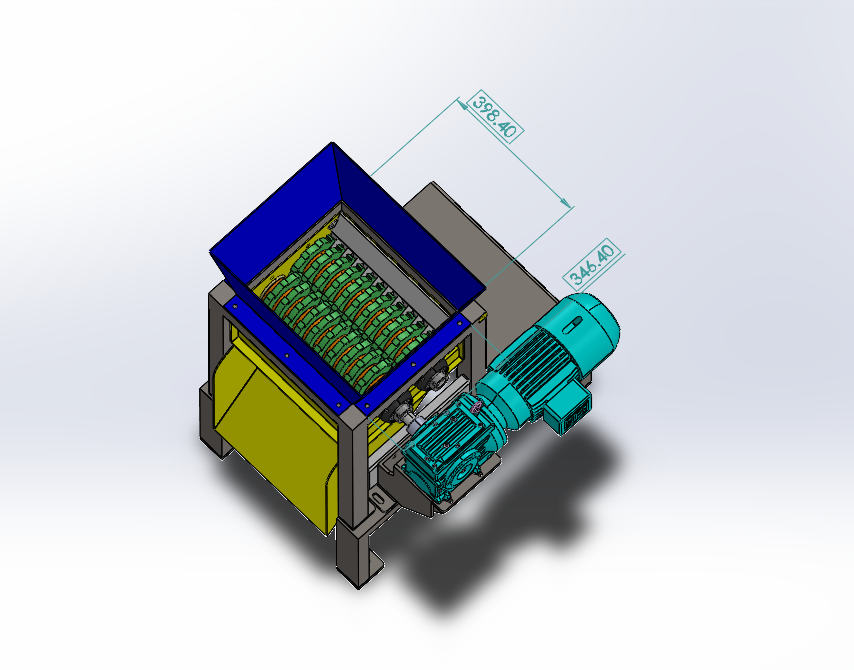

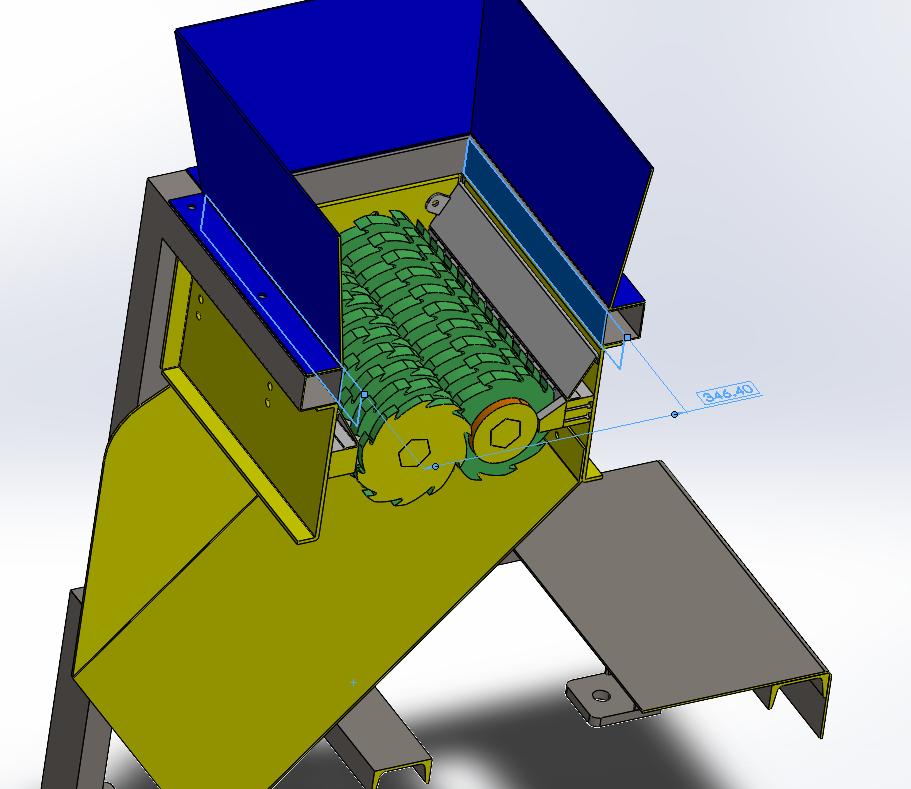

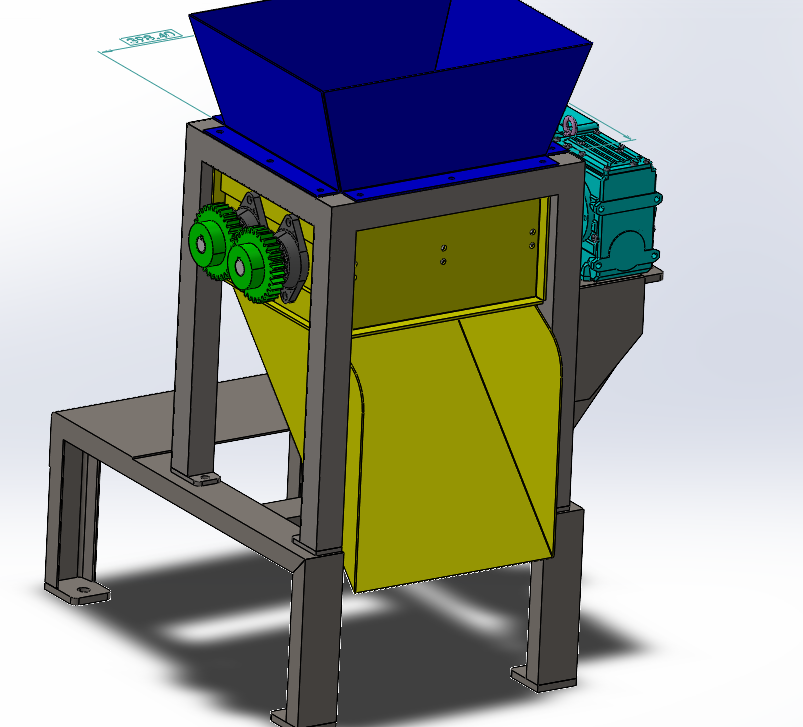

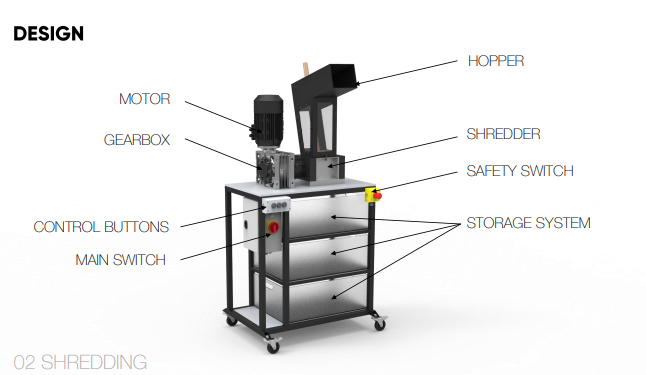

Nevertheless, amidst this environmental crisis lies an opportunity for transformation. Initiatives worldwide are pioneering innovative methods to repurpose and recycle plastic waste. Technologies for plastic shredding and recycling are emerging, enabling the conversion of discarded plastics into raw materials for new products. Companies are embracing sustainable practices, incorporating recycled plastics into their production processes, thereby reducing their environmental footprint.

**Turning the Tide:**

The shift towards a circular economy—one where materials are reused, repurposed, and recycled—is gaining momentum. From employing biodegradable alternatives to creating awareness about responsible consumption, individuals and organizations are advocating for change. Governments are implementing policies to regulate plastic usage and promote sustainable practices, fostering a collective effort to combat plastic pollution.

**Seizing Opportunities for Change:**

The transition towards a plastic-free environment isn’t just an obligation but a chance for innovation and economic growth. By harnessing plastic waste, we create employment opportunities in recycling industries, foster technological advancements, and build a sustainable future. Transforming plastic pollution into a valuable resource not only cleanses our surroundings but also fuels progress and improves our quality of life.

**Towards a Cleaner Future:**

It’s paramount to intercept plastic at its source—rivers, oceans, and other reservoirs—to prevent further contamination. Implementing comprehensive waste management strategies, supporting recycling initiatives, and encouraging conscious consumption habits are pivotal steps towards a cleaner, healthier planet.

In conclusion, the journey from the genesis of plastic to its pervasive pollution marks a critical turning point. Embracing innovative solutions and collective action is imperative in combating this crisis. Let us endeavor to transform plastic pollution into an opportunity for a sustainable and prosperous tomorrow.

Together, let’s shred the burden of plastic pollution and pave the way towards a greener, cleaner future.

This article aims to cover the evolution of plastic pollution, its impact, and the potential for positive change by repurposing plastic waste into opportunities for a better environment and economy.