Hello I havent been posting anything for a while , but today is the day 🙂

As you may already know . The shredder motor has to be connected somehow to the shredding module itself .

It is possible to connect the motor rigidly – i.e. with a coupling in the style of a steel bushing with holes to fit both the geared motor shaft and the shredder shaft . This is an inexpensive way of doing it, but it transmits vibrations and can destroy the machine by knocking due to misalignment.

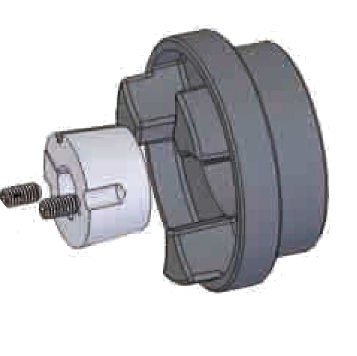

This is why I use HRC clutches with several elements. (a more expensive solution – but the only correct one).

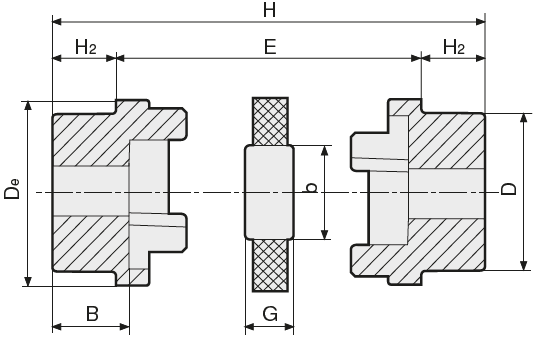

HRC claw couplings are very robust couplings which, depending on the size and the coupling used, can transmit high torques while operating at very high speeds. As they are flexible couplings, they consist of independent hubs and a coupling, as well as components that are resistant to moisture, oil and dust.

HRC couplings dampen vibrations very easily and effectively and allow operation with shaft misalignment. They are used mainly in machine and plant construction, wherever high torque transmission is required. The efficient operation of these couplings and their really good mechanical characteristics have made HRC couplings very widely used.

If you are planning to build a shredder, look for this type of coupling on our website or just contact me for quote.